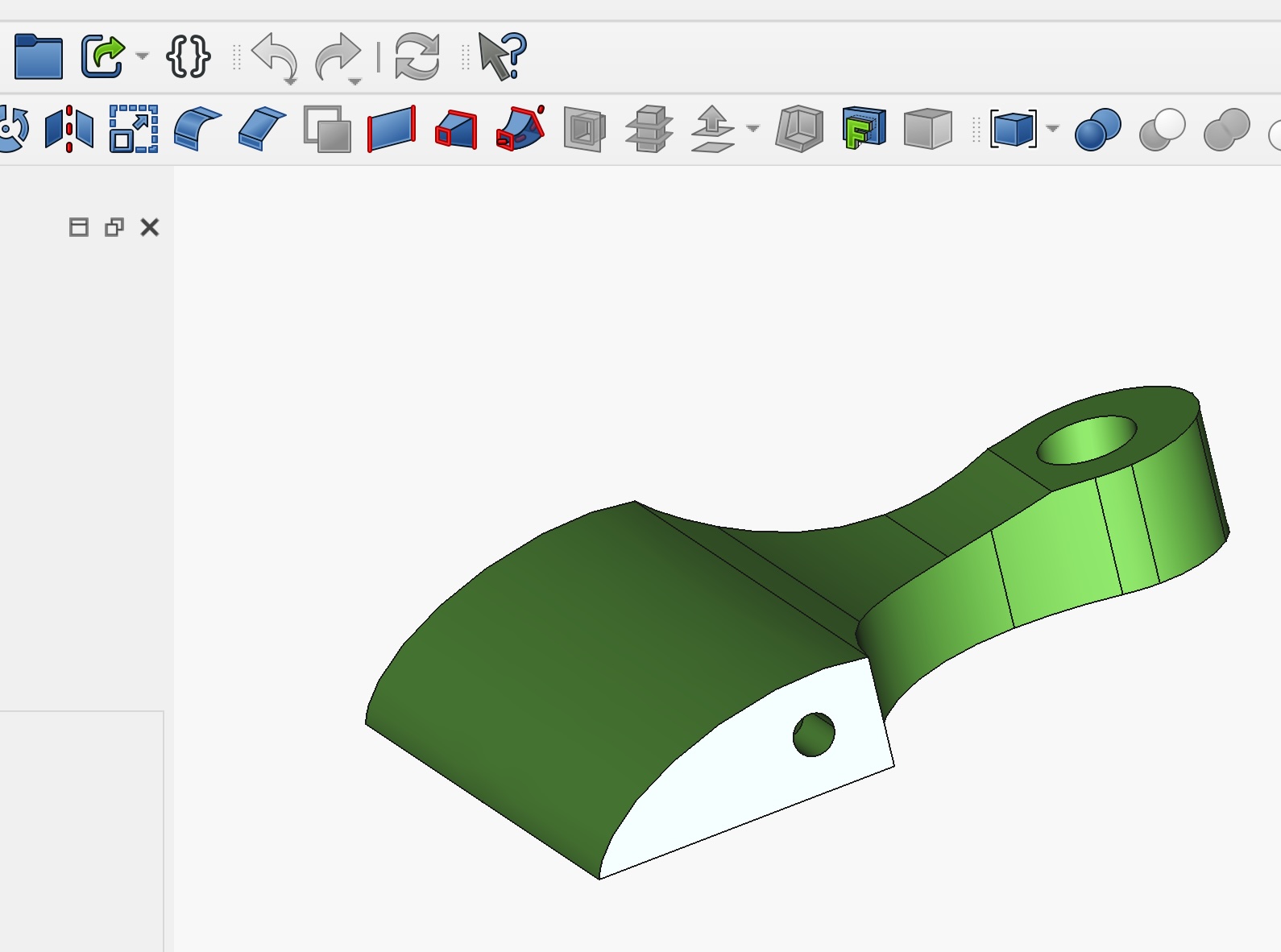

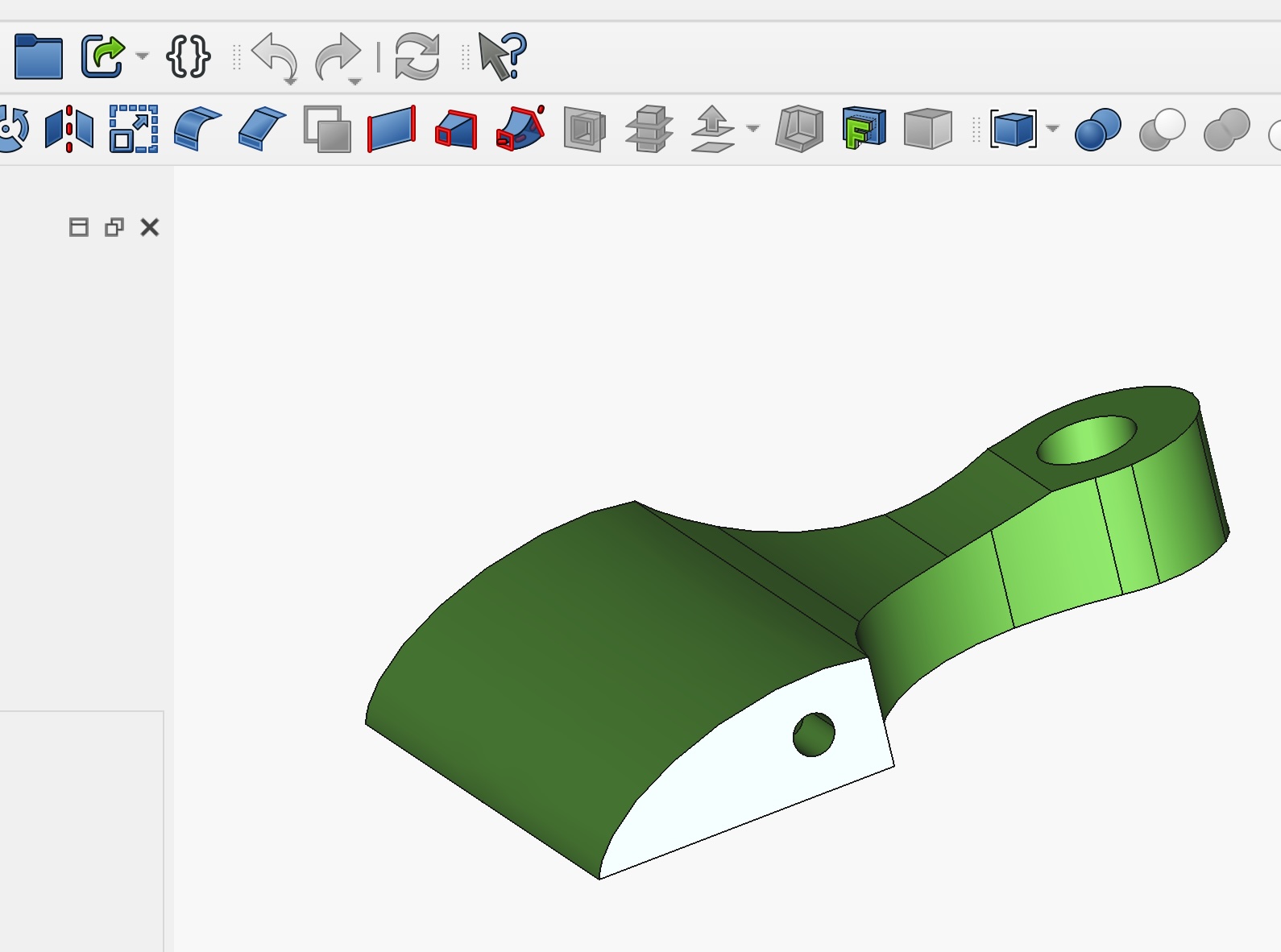

Handled or unhandled, 45° - 50° bedding, brass or steel sides, and a dense hardwood infill. These planes range from 6" - 8" long.

Planes

Handled or unhandled, 45° - 50° bedding, brass or steel sides, and a dense hardwood infill. These planes range from 6" - 8" long.

A longer sole for truing panels and jointing edges. The core pattern is a 14" plane, but longer can be made.

Rabbet planes and their cousins. These range from coachmaker-style rabbets to oddball joinery planes that fall outside the regular patterns.

Available now

Work in progress

Process

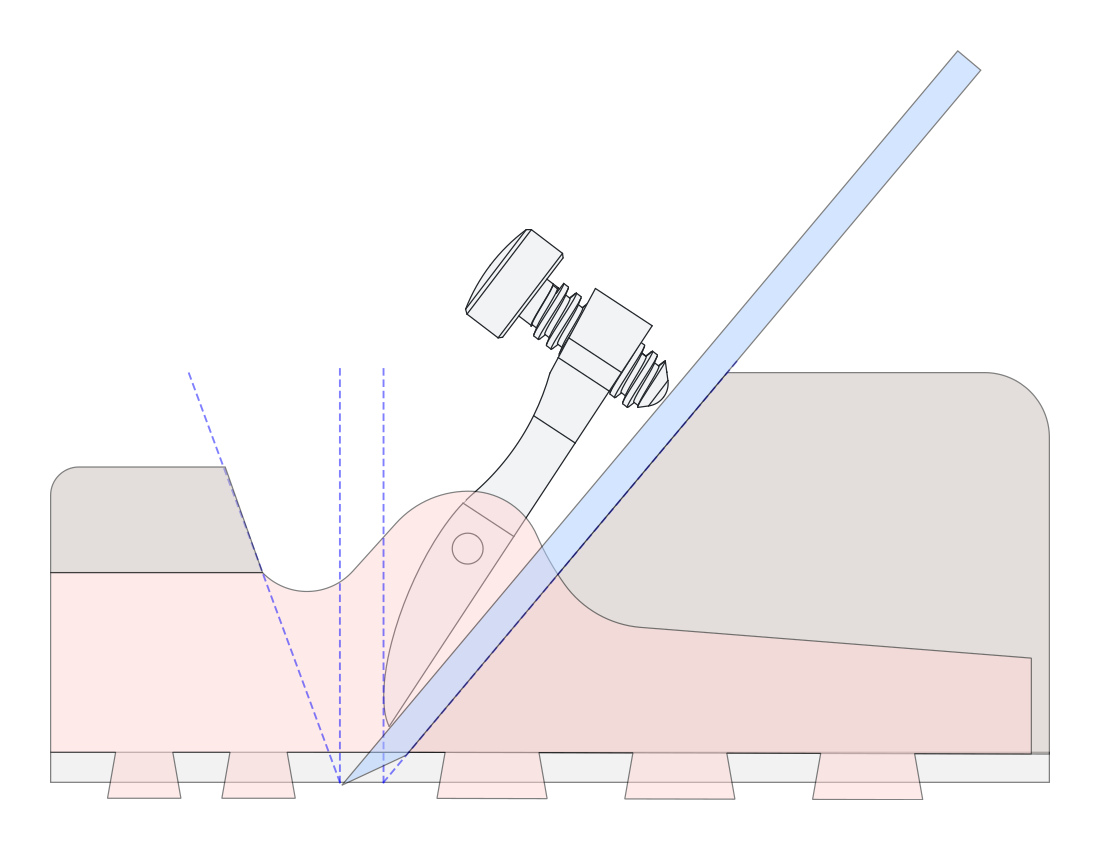

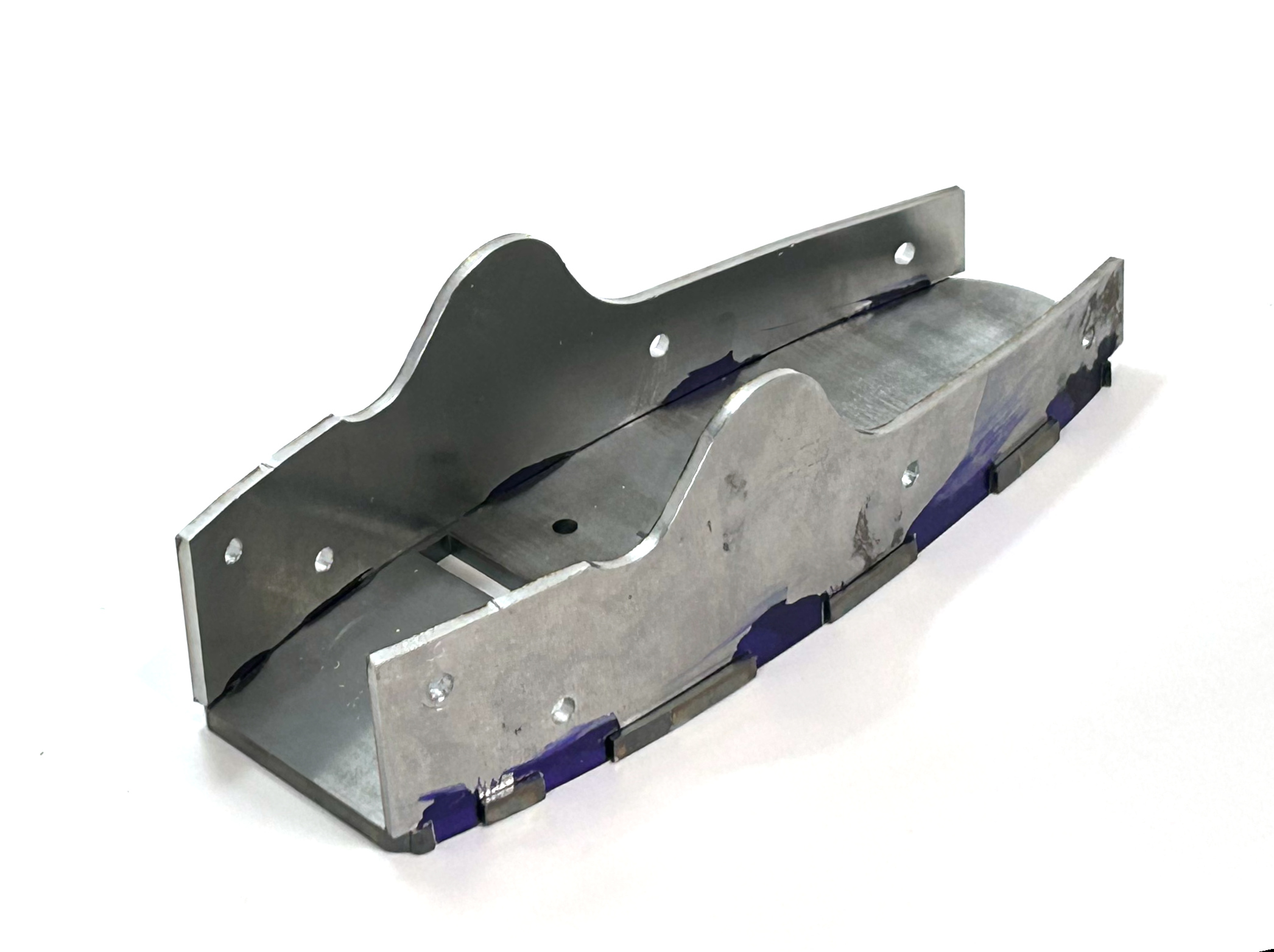

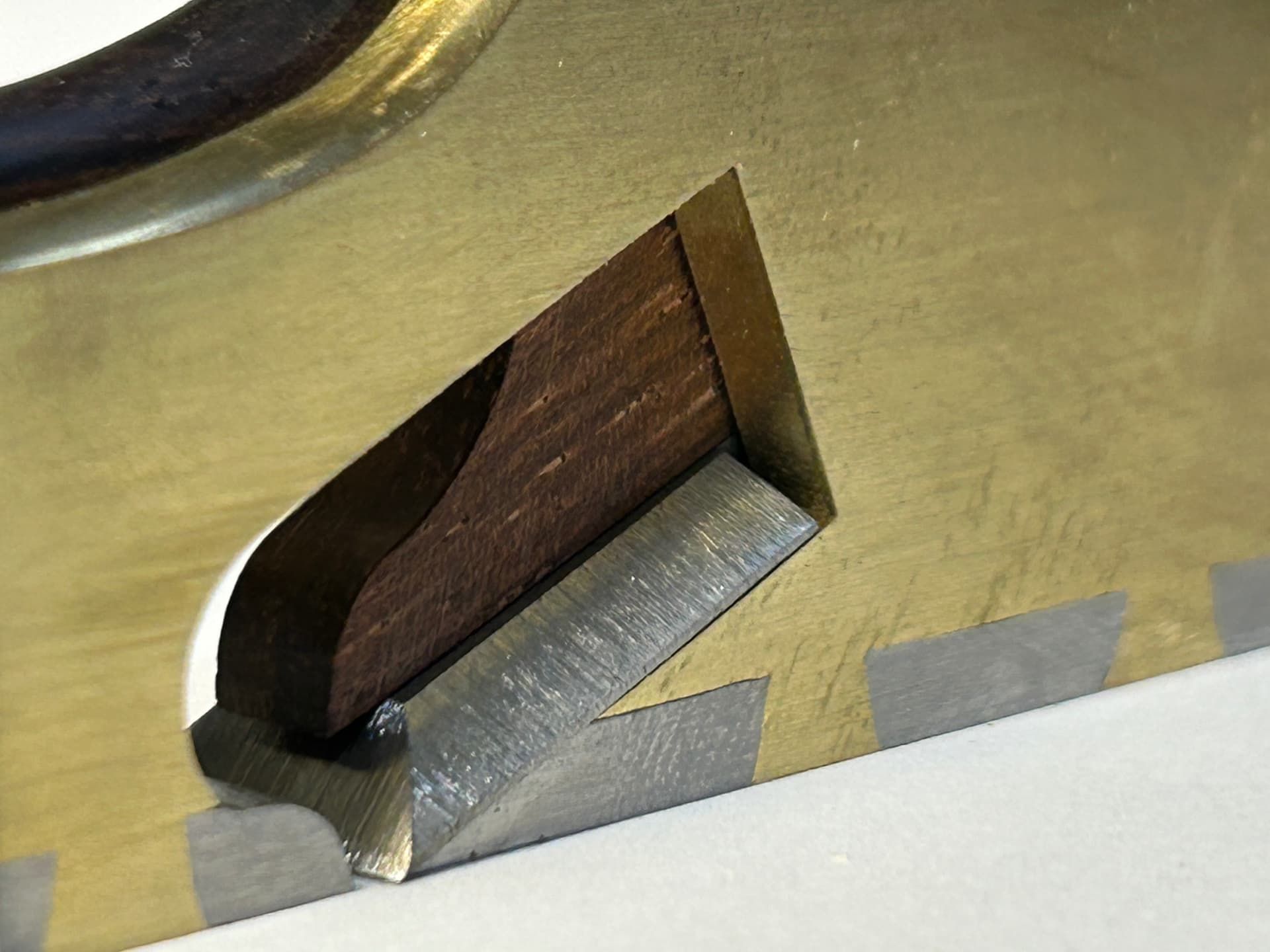

My planes are built along traditional British infill lines: metal shells mechanically joined at the edges with traditional dovetails, solid wood infills, and thick irons. Although my designs begin as close copies of antiques, the aim is never to recreate a museum piece. I take full advantage of advances in technique, tooling, and metalurgy over the last 150 years, and have updated the designs to make the most of them where it makes sense.

Why an infill?

You do not need an infill handplane. A well-tuned modern bench plane from Lie-Nielsen or Veritas will leave an excellent surface for a fraction of the cost. An infill isn’t competing in that market. These planes occupy the space between sculpture and instrument: built slowly, by hand, with the kind of material choices and joinery that only make sense when the object itself is the point. The metalwork, the wood selection, the dovetailing, the bedding, none of it is optimized for efficiency or volume.

That an infill also happens to be an excellent working plane is a bonus. Many put them to daily use; others treat them as functional art, ready for work whenever the mood strikes. Either approach is valid. Like a work of sculpture, an infill handplane has little to do with need and more to do with the joy that having and using it brings the owner.

About

This is a one-person workshop focused on one-off or very small-batch infill handplanes. I do not take commissions. Planes are all built on spec and posted when they are done. I expect to finish a handful of planes a year; they’ll be listed under ‘Available now’ when ready.